Epsilon EP

Epsilon EP

10-240 VAC, Single Phase, 50/60Hz Input

2.2 - 16.0A RMS (4.4 - 32 Peak)

115V / 230V

The compact, easy-to-use Epsilon EP servo drive

is scalable from a simple amplifier to a completely programmable 1.5-axis

motion controller. For added application flexibility, the Epsilon EP

is available in three models: Epsilon EP-B (base), Epsilon EP-I

(indexer), and Epsilon EP-P (programming).

Each model is available with five drive power stages:

2.2A, 4.0A, 6.5A, 9.0A and 16.0A. This provides the capability to deliver

over 198lb-in (22.4Nm) of torque at the rated motor speed and 396lb-in

(44.8Nm) of peak torque for high demanding, pulse-duty applications. The

Epsilon EP offers four of the most popular network connections for

industrial controls: RS485 (with standard Modbus RTU interface) is on

all models allowing interfacing to PC tools, simple HMI’s and

drive-to-drive configurations.

Optional ProfiBus DP and DeviceNet communication

configurations are available for system integration to common PLC

platforms. EtherNet (standard on every Epsilon EP-P) opens up a world

of interfacing possibilities (see the communications section under the Options

tab for more information).

Features

Integrated Control

Integrated Control

Our Epsilon EP servo drive product line offerings include integrated

motion control solutions. The Epsilon EP product line offers product

scalability with base, indexer and programming variants.

Variants and their respective solutions include:

-

Epsilon EP- P - Programmable -

Create complete user programs to sequence the motion control

-

Epsilon EP- I - Indexer drive -

Position controller provides Home, Index, and Jog motion profiles

-

Epsilon EP - Base drive - Ideal

for servo applications utilizing an external motion controller

|

PowerTools Pro

|

√

|

√

|

√

|

|

CTSize

|

√

|

√

|

√

|

Performance

Advantage

Control Techniques has incorporated several advanced features and

capabilities in the Epsilon EP family to make these drives even more

powerful and easier to use. The key features are incorporated into the four

variants of this product line. The four variants are:

Epsilon

EP-B – Base

The base drive is ideal for servo applications utilizing an external

motion controller. It accepts an analog command signal and sends out

position feedback. The EP-B has the unique capability of combining an

analog command with a preset velocity for trimming or advance/retard

operations. The EP-B drive is an excellent choice for stepper replacements

or centralized control systems.

Epsilon

EP-I or EP-IDN – Indexer

The EP-I drive is a highly capable position controller that provides

Home, Index, and Jog motion profiles. The EP-I holds up to16 unique indexes

that also can be chained together to create complex motion profiles. The

EP-I has a unique alternate mode feature whereby it can perform an Index or

Home function and then switch to an alternate mode such as Analog Torque,

Analog Velocity, or Pulse Follower mode on the fly! This compact indexing

drive is a cost effective solution for countless applications.

Epsilon EP-P, EP-PDN and EP-PPB –

Programming

The EP-P drive provides the highest level of control by allowing the user

to create complete programs to sequence the motion control along with other

machine functionality. The EP-P can be used to solve the most complex

motion applications and still be easy to use thanks to Control Techniques'

FREE PowerTools Pro configuration software. PowerTools Pro uses simple

drag-and-drop and fill-in-the-blank screens that make setup a snap. User

programs are created using a text-based motion language that is as easy to

read as it is to program. If you don’t know the command, simply drag it

in from the drop-down box and PowerTools Pro will assist you with the

syntax. With intuitive software and plenty of online help, programming this

servo drive is truly “Motion Made Easy!”®

Additional features

include:

Real-Time Program

A Real-Time Program (RTP) is a user program that executes in a single servo

update. A RTP allows synchronous execution of a user program with the

internal motion kernel which enables the possibility of real-time

modification of motion profiles, monitoring of key performance indicators,

or to make time critical calculations needed to get the most out of your

motion control system.

Electronic

Camming

Programming electronic cams has taken a huge step forward with

Control Techniques' easy-to-use camming functions. PowerTools Pro

offers a unique graphical interface which show the motion engineer exactly

what the cam profile looks like in polar or linear coordinates. Cam data

can be imported from a CAD system or entered directly from the PowerTools

Pro software or even self generated within a user program. Epsilon EP

supports several different types of interpolation types including linear,

cosine, square, cubic spline, and jerk free offering flexibility in

trajectory generation. Cam profiles can be started as easily as turning on

an input, with no user program involved. Of course for advanced

capabilities, user programs can be also used enabling access to a wealth of

cam information and dynamically monitoring.

Modbus Master

Modbus Master takes machine control capability to a whole new

level. No longer limited to the drive's on-board I/O, the Modbus Master can

manage a very large number of I/O and communicate updates to any Modbus

follower device, giving machine builders extensive control options.

Position TrackerTM

Analog position control and Fieldbus position control allow the Epsilon EP

to replace an expensive PLC motion control module with a simple, low cost

analog signal or Fieldbus register. With Position Tracker, the closed loop

feature of the position controller has been integrated into the drive

itself. The user simply sends the drive an analog or Fieldbus signal that

is proportional to the absolute motor/actuator position. Advanced features

such as "teach" functions also contribute to faster set up.

Built-in Timers

These timers provide a simple and accurate way to trigger an action based

on a previously initiated time delay. Select from up to seven different

timer types to match your needs.

Ethernet Programming

The EP-P drive uses common Ethernet protocols for all levels of networking

ranging from applications setup and monitoring to communicating to PLC’s

via Ethernet/IP or connecting to an operator panel using Modbus TCP/IP.

Dual Loop Mode (EP-P)

For those applications where it is required to command

motion based on feedback from a linear encoder, for example, PowerTools Pro

has the functionality to configure the EP-P drive for Dual Loop mode.

Whether the feedback is linear or rotary, a user can define motion in terms

of the secondary feedback and let the Epsilon calculate the relative motion

required by the motor.

Technology for

reliability and performance

-

Flexible bus voltages DC, AC 10V to 264V

-

5 Drive Power Options: 2.2, 4, 6.5, 9 and 16 Amps

-

1 to 200 lb-in continuous torque range

-

Drive types: Base, Indexing, and Programmable

Indexing and Programmable drives can be ordered with optional DeviceNet

or Profibus

-

Easy install, setup and operation

-

Compact, space saving design, six-inch (152 mm) panel

depth including cables

-

Pluggable connectors, Standard D-Shell and Screw

Terminals

-

State-Space Observer Control, which allows 10-1 inertia

mismatch out of the box, and 50-1 with tuning

-

FREE PowerTools software, and upgrades

-

Programmable, optically-isolated I/O

-

RS485 serial communication interface using Modbus

protocol

-

Ethernet/IP and Modbus TCP/IP standard on the Epsilon

EP-P programmable drive

-

Field programmable flash memory firmware (upgrades are

free)

-

Wide variety of motor combinations: Unimotor HD, Unimotor

FM, MG, NT, XV

-

Auto-Tune support for any servo motor with encoder

feedback

-

24 VDC input for logic power supply

Specifications

and Dimensions

Power Requirements

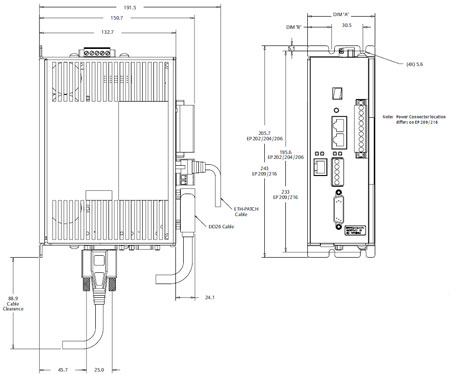

AC Input Voltage, 47-63 Hz

EP 202/204/206: 1Ø, 20 to 264 VAC

EP 209: 1Ø, 90 to 264 VAC

EP 216: 3Ø, 90 to 264 VAC

(240 VAC for rated performance) SCCR 10kA

DC Input Voltage

EP 202/204/206: 10-340 VDC

EP 209/216: 140-340VDC

AC Input Current (max. continuous)

EP202: 5.0 Arms (140A for 2 ms inrush)

EP204: 8.5 Arms (140A for 2 ms inrush)

EP206: 12.0 Arms (140A for 2 ms inrush)

EP209: 16 Arms (34A for 5 ms inrush)

EP216: 16 Arms (34A for 5 ms inrush)

Output Current Continuous (rms) / Peak (4

sec.)

EP202: 2.2A / 4.4A

EP204: 4.0A / 8A

EP206: 6.5A / 13A

EP209: 9.0 A / 18A

EP216: 16.0A / 32A

Continuous Output Power

EP202: 0.77 kW

EP204: 1.27 kW

EP206: 1.77 kW

EP209: 2.32 kW

EP216 3Ø: 4.8 kW

EP216 1Ø: 2.32 kW

Switching Frequency 10 kHz

External Logic Supply +18 to 30 VDC @ 0.5A

Encoder Supply Output +5 VDC, 250 mA

I/O Supply +10 to 30 VDC

System Efficiency 93%

Cooling Method

Convection EP202 through EP209 Internal Fan EP216

Regeneration

Internal Energy Absorption (115V / 230V)

EP202: 39 Joules / 8 Joules

EP204: 58 Joules / 12 Joules

EP206: 97 Joules / 20 Joules

EP209: 117 Joules / 24 Joules

EP216: 132 Joules / 28 Joules

External: Connection to external resistor, EP 202-209: 30

Ohm min, 12A peak, 2 kW avg.

EP216: 20 Ohm min, 20A peak, 5 kW avg.

Drive Control Inputs

Analog: (1) +/-10 VDC, 14 bit, 100k Ohm,

Differential

Analog Max. Input Rating: Differential +/-14 VDC, Each

Input with Reference to Analog Ground +/-14 VDC

Digital: (16) (5 on EP-B) +10 to 30 VDC, 2.8k Ohm,

Sourcing, Optically Isolated

Pulse: (1) Differential RS-422, 1 MHz/Channel, 50% Duty

Cycle

Single Ended: (1) TTL Schmitt Trigger 500 kHz/ Channel,

50% Duty Cycle

Motor Over temperature: 0 to +5 VDC, 10k

Ohm, single ended

Drive Control Outputs

Analog: (2) +/-10 VDC, 10 bit, Single-ended 20mA

Digital: (8) (3 on EP-B) +10 to 30 VDC, 150 mA,

Sourcing Optically Isolated

Short Circuit Protected

Pulse: Differential RS-422 and TTL compatible, 20

mA/Channel Sink or Source

Environmental

Rated Ambient Temperature: 32° to 104°F (0° to 40°C) for

rated performance

Maximum Ambient Temperature: 32° to 122°F (0° to

50°C) with power derating of 3.0%/1.8F (1°C) above 104°F (40°C)

Rated Altitude: 3280’ (1000 m)

Maximum Altitude: For altitudes >3280’ (1000 m)

derate output by 1%/328’ (100 m )

Vibration: 10 to 2000 Hz @ 2g

Humidity: 10 to 95% non-condensing Storage Temperature:

-13° to 167°F

(-25° to 75°C)

Ingress Protection: IP-20

Serial Interface

2 RS485 connectors for multi-drop

applications Modbus RTU w/ 32-bit extension,

9600 to 19.2k Baud

Ethernet Interface (EP-P only)

1 RJ-45, Modbus TCP/IP or EtherNet/IP

DeviceNet (EP-xDN models only)

Power Consumption: 25 mA

Baud Rates: 125, 250 and 500 kps

Node Addresses: 00-63

Profibus-DP (EP-PPB model only)

Baud: 1.5 to 12 Mb, Address Range: 00-126

|

EP202 / EP204 -B,-I,-IDN

|

53.3

|

11.4

|

1.63

|

|

EP206-B,-I,-IDN

|

71.6

|

11.4

|

1.91

|

|

EP202 / EP204 -P

|

68.3

|

26.1

|

1.77

|

|

EP206-P

|

86.3

|

26.1

|

2.04

|

|

EP209 / EP216 all models

|

86.3

|

26.1

|

2.49

|

Communications

EtherNet,

Profibus, DeviceNet

Optional ProfiBus DP and DeviceNet communication

configurations for system integration to common PLC platforms, and Ethernet, standard on every Epsilon EP-P, opening up a whole new world of

interfacing possibilities are also available. The Epsilon EP-P’s

EtherNet port supports EtherNet/IP, Modbus TCP/IP, HTTP, and SMSC with up

to eight simultaneous connections (sockets) at a single time. That means

you can be online with your HMI at the same time as your PC Tools,

monitoring drive status remotely via a web browser, and have the drives

communicating to each other for a true distributed control system, all at

the same time!

The Ethernet port is configured to communicate using two

industrial protocols: EtherNet/IP and Modbus TCP/IP. Communication setup

is easily done with drag and drop drive information into the Ethernet

Mapping. The EP-PDN, EP-IDN (DeviceNet) and EP-PPB (Profibus) are the

Epsilon EP drives with these industry standard fieldbus options.

The EP-P has built in RS485 multi drop serial ports. The

ports use industrial standard Modbus RTU. Making connectivity easily with

many PLC and HMI products.

Position Tracker™ – Fieldbus Indexing replaces

expensive PLC motion controllers with fieldbus communications. Motion

profiles can be dynamically changed on the fly.

|

EtherNet

|

|

|

Standard - all units

|

|

Profibus

|

|

|

√

|

|

DeviceNet

|

|

√

|

√

|

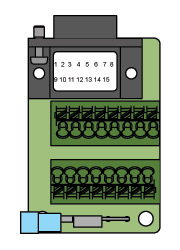

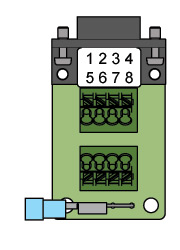

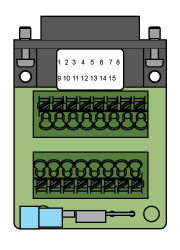

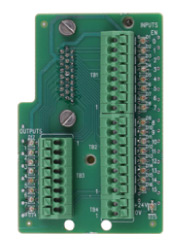

Breakout Boards

STI-ENC

Motor Feedback Breakout Board

STI-SNCI

Drive Sync In Breakout Board

STI-SNCOA

Drive Sync Out and Analog In/Out Breakout Board

STI-24IO

Screw Terminal Interface Breakout Board

Cables

DDC-RJ45-xxx

Drive RS485 to Drive RS485

CT-USB-CABLE

PC USB Port to Drive RS485 Serial Interface

ETH-PATCH-xxx

Ethernet to Drive

EIO26-xxx

Epsilon EP I/O

SNCFLOA-xxx

Drive Sync Out

SNCMD-815-xxx

Drive Sync Out to FM-3/4 Module In

SNCFLI-xxx

Drive Sync In

SNCMD-89-xxx

Drive Sync In from FM-3/4 Module Out

PSBAA-xxx, PBBAA-xxx**

Motor Power Cable for FM Motors

SIBAA-xxx**

Motor Feedback Cable for FM Motors

XTMDS-xxx*

Motor Power Cable for 40, 60 & 80 mm XV Motors

XTBMS-xxx*

Motor Brake Cable for 40, 60 & 80 mm XV Motors

XUFTS-xxx*

Motor Feedback Cable for 40, 60 & 80 mm XV Motors

XCMDS-xxx or XCMBBS-xxx*

Motor Power (+ Brake) Cable for 130 mm XV Motors

XUFCS-xxx*

Motor Feedback Cable for 130 mm XV Motors

CMDS-xxx or CMMS-xxx*

Motor Power Cable for NT Motors

CBMS-xxx*

Motor Brake Cable for NT Motors

UFCS-xxx*

Motor Feedback Cable for NT Motors

CT-COMMS

Drive RS485 to Drive RS485

SNCDD-915-xxx

Drive Sync Out to Drive Sync In

Cable Notes:

* Flex duty versions available

** Flex duty cable

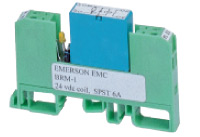

Miscellaneous

BRM-1

Drive Brake Relay

SCSLD

Master Synchronization Encoder

ETH-S8

Ethernet 8-port Switch

Electromagnetic

Compatibility Filters

Line Filters

Electromagnetic Compatibility Filters

DB Resistors

E-Stop Duty, Internal and Enclosed Dynamic Braking Resistors

Automation

and motion programming software

|

|

|

PowerTools Pro - Advanced motion control

programming

|

|

Advanced motion control programming for Unidrive SP

(with the SM-EZMotion module) and Digitax ST-Z drives

and Epsilon EP, FM-3E and FM-4E modules

|

|

|

Our free PowerTools Pro software enables you to fully realize the

power of our SM-EZMotion, FM

modules and Epsilon EP servo

systems. A familiar Microsoft® Windows™ interface

provides operators and machine builders with the tools needed to

access everything they need for complete servo control—PLS,

Queuing, Analog-In, User Variables, High-Speed Capture, Electronic

Gearing, and more.

Setup and Programming is made easy with our free, drag and drop,

PowerTools Pro software which programs the entire “Motion Made

Easy”™ product family. PowerTools Pro is free of charge and can

be obtained from our download section.

Developing motion applications with PowerTools Pro is a simple

“five step, top-down process”. The five steps are displayed

within an explorer bar that allows easy navigation. Each step is

configured using simple check boxes, drop down selections and drag

and drop functionality.

The five steps are:

- Hardware Configuration

- Drive Setup

- I/O Setup

- Motion

- Programs

PowerTools Pro is a “BASIC”-like programming language

enabling users to develop more complex applications and sequencing

with functions being selected by dragging and dropping onto the work

area.

Our PowerTools Pro software enables you to fully realize the

power of our entire servo product line including; Digitax ST,

Epsilon EP, MDS and Unidrive SP. A familiar Microsoft®

Windows™ interface provides operators and machine builders with

the tools needed to access everything they need for complete servo

control — Motion Profile Setup, User Units, Motor Auto-tune,

Electronic Gearing, Network Configuration, and many other advanced

features.

Note: New advanced PowerTool Pro 5.0 features

are not supported on FM3 & FM4 modules, but are supported on our

FM3E, FM4E modules and all other servo drive products.

Assignments – Use our "Virtual

Wiring" to create programs right out of the box, without

writing a single "line of code." For example; the

assignment screen simply drag-and-drop the desired machine function

onto the digital inputs and outputs.

Indexes – Setting up indexes is easily

accomplished by filling in the screen’s blanks to create an index

profile. Select from Incremental, Absolute, Registration, or Rotary

Plus and Minus types. With our Position Tracker synchronization can

be easily achieved by simply adjusting the time bar. Choose the time

base of the index by selecting either real time or synchronized to a

master.

Network – Whatever Fieldbus you are using,

setting up network communications is quick and easy.

Fill-in-the-blank, drag-and-drop procedures are used to get your

drives communicating. PowerTools Pro diagnostics couldn’t be more

intuitive, allowing real-time monitoring of the actual data being

sent and received.

Camming – Cam data is easily entered within

PowerTools Pro, and the Cam graphing tool is second to none, with

multiple interpolation types available.

|

|

|

|

CTSize - Drive sizing software

|

CTSize is an easy-to-use servo sizing software package

that helps you size your application using a

step-through process

|

CTSize -

Drive sizing software for servo drives

CTSize is an easy-to-use servo sizing software

package that makes product selection and sizing an

easy step-through process. Selecting the optimum

system is achieved by simply going through the five

tabs: Load, Motion, Reduction, Selection and

Results.

Important Note: CTSize is currently

not compatible with Windows® 7. It is

functional with prior versions of Windows®

operating systems such as Windows XP.

It is possible to run CTSize in Windows®

7 operating in Windows® XP mode. Software

downloads from Microsoft are required in order to add

XP mode.

Windows® and Microsoft®

are registered trademarks of the Microsoft Corporation.

- Tab

Structured Layout— Easily

step through your application from

Load and Motion details to Product

Selection by clicking on the links to

one of the five tabs: Load, Motion,

Reduction, Selection and Results.

Start with the information you know

and let the sizing software do the

rest.

- Pre-Configured

Applications — Leadscrew,

Rack and Pinion, Conveyor, Cylinder,

Feedroll and User Defined applications

ease sizing by requiring only the

necessary inputs parameters base on

the selected load type.

- Pre-Defined

and Multi-Segment Profiles —

Entering in a motion profile is easily

done by selecting one of the four

basic profile types or by creating

complex profiles with the

multi-segment function.

- Multiple

Gearbox Reductions — Select

up to three stages of speed reduction

from five types – Belt/Pulley,

Gear/Gear, Chain/Sprocket, User

Gearbox and Catalog Gearbox.

- Organized

Results — The Results are

organized in simple and clean fashion

with the optimum selection parameters

and speed/torque displayed at the top

and alternative solutions listed at

the bottom. The list of alternative

solutions can be sorted by a variety

of filters to quickly find the drive

and motor models.

- Inertia

Calculator — Calculate

inertia’s of complex shapes by

selecting from one of six pre-defined

shapes and adding or subtracting their

individual inertias.

- User

Configurable Units — The

user can select Metric or English

units or setup Custom units.

- Extensive

Help File — Explains each

page of software in a detailed and

easily understandable format.

- Embedded

Links to Websites — Easily

find contact information for

additional support or drawings of

drives and motors.

- Detailed

Printout — Easily document

your results with the detailed

printout that sums up all the

application requirements and

drive/motor combination information.

|

|

|

|

|

|

|