Application

- Standard Dry Type Ventilated Transformers are cooled by natural

circulation of the surrounding air through its windings. For trouble

free operation and long life expectancy, the ventilating air must be

reasonable free from dust, moisture or other damaging corrosive

fumes. For this reason, standard Dry Type ventilated transformers

are normally installed in suitable, indoor locations where they are

protected from damaging elements.

- Some specifications require installation of transformers in

hazardous surroundings where the above condition can be met.

- Epoxy Potted Transformers (also referred to as Epoxy Resin

Encapsulated) are designed for such conditions.

- Typical areas of use include: Corrosive environments - Petro-Chemical,

steel, pulp and paper industries; Damp conditions - Mines,

pump-houses, underground or rooftop service areas; Airborne dust,

conductive particles

Features

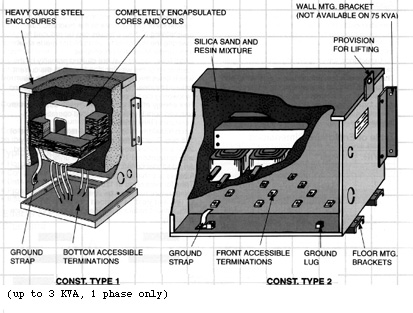

- Mixture of silica sand resin forming a solid mass completely

encloses and protects the core and coil, also significantly reduces

audible noise.

- Windings utilize Class 220oC Insulating rated for 150oC

Rise, but designed to operate at 115oC maximum.

- The transformer's core is solidly grounded.

- Enclosure constructed from heavy gauge steel, coated with ASA#61

grey powder paint

- Suitable for NEMA/CSA Type 3R and Type 4 Enclosure applications

for both indoor and outdoor

- Spacious wiring compartment, cool and easily accessible (bottom or

front access may depend on size)

- Standard Primary Taps

- CSA Certified, File No. LR34493

- UL Listed, File No. E108255

- ISO9001 Quality Certification

Common Part Numbers & Typical Information

|

Typical Sizes

|

1-Phase 600-120/240

|

1-Phase

480-120/240

|

Approximate Weight

|

Enclosure Size No.

|

Enclosure Size No.

|

Dimensions W x D x H (inch)

|

|

0.250KVA

|

SC0.250JK/EP

|

SC0.250HK/EP

|

17LBS

|

1E

|

1E

|

5x4.25x9.75

|

|

0.500KVA

|

SC0.500JK/EP

|

SC0.500HK/EP

|

20LBS

|

1E

|

2E

|

5.87x4.87x10.25

|

|

0.750KVA

|

SC0.750JK/EP

|

SC0.750HK/EP

|

23LBS

|

1E

|

3E

|

7.5x6.12x11

|

|

1KVA

|

SC1JK/EP

|

SC1HK/EP

|

27LBS

|

2E

|

4E

|

9.75x12x16.25

|

|

1.5KVA

|

SC1.5JK/EP

|

SC1.5HK/EP

|

40LBS

|

3E

|

5E

|

15.5x14x19.25

|

|

2KVA

|

SC2JK/EP

|

SC2HK/EP

|

45LBS

|

3E

|

6E

|

15.5x15x25.5

|

|

3KVA

|

SC3JK/EP

|

SC3HK/EP

|

55LBS

|

3E

|

7E

|

15x15x15

|

|

5KVA

|

SC5JK/EP

|

SC5HK/EP

|

170LBS

|

4E

|

8E

|

21x18x17.5

|

|

7˝KVA

|

SC7JK/EP

|

SC7HK/EP

|

180LBS

|

4E

|

9E

|

21x22x20

|

|

10KVA

|

SC10JK/EP

|

SC10HK/EP

|

235LBS

|

5E

|

10E

|

32x22x25

|

|

15KVA

|

SC15JK/EP

|

SC15HK/EP

|

296LBS

|

5E

|

|

|

|

25KVA

|

SC25JK/EP

|

SC25HK/EP

|

355LBS

|

6E

|

|

|

|

37˝KVA

|

SC37JK/EP

|

SC37HK/EP

|

395LBS

|

6E

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical Sizes

|

3-Phase 480-208Y/120

|

3-Phase 480-208Y/120

|

Approximate Weight

|

Enclosure Size No.

|

|

|

|

3KVA

|

BC3JM/EP

|

BC3HM/EP

|

|

|

|

|

|

6KVA

|

BC6JM/EP

|

BC6HM/EP

|

130LBS

|

7E

|

|

|

|

9KVA

|

BC9JM/EP

|

BC9HM/EP

|

200LBS

|

7E

|

|

|

|

15KVA

|

BC15JM/EP

|

BC15HM/EP

|

415LBS

|

8E

|

|

|

|

30KVA

|

BC30JM/EP

|

BC30HM/EP

|

536LBS

|

9E

|

|

|

|

45KVA

|

BC45JM/EP

|

BC45HM/EP

|

645LBS

|

9E

|

|

|

|

75KVA

|

BC75JM/EP

|

BC75HM/EP

|

1300LBS

|

10E

|

|

|

Available Options Include:

- Temperature Rise (80oC)

- Other Primary or Secondary Voltages

- Different frequency (other than 60Hz)

- Stainless Steel Enclosure & Hardware

- Electrostatic Shield (single, double, triple or multiple/ultra)

- Custom sizes (specific KVA ratings)

- K-Factor Rated (K4, K9, K13, K20, K30)

- Special Paint/Finish

|