|

The Quantum III

delivers a complete DC drive package that integrates the intelligence of

the Mentor II with a space saving design that incorporates many accessories

typically required in the North American market.

The

Quantum III delivers a DC drive package that integrates the

intelligence of the Mentor II with a space saving design that incorporates

many accessories typically required in the North American market. It is

easily configurable to control motor speed, voltage or current using standard

internal settings. Set-up is convenient using the drive keypad, CTKP remote

keypad, or MentorSoft, a Windows based drive configuration tool. These drives have powerful diagnostic and

communication abilities. The simple addition of the MD29 applications card

enables users to incorporate custom or proprietary process control

application programs to their drive. The Quantum III also provides extensive

communication protocol options. The integrated design includes fuses, a

DC loop contactor, and 115 VAC interface logic control, making it an ideal

choice for end users with space constraints.

The

Quantum III offers a compact DC package solution. You'll also find the

Quantum III on OEM equipment and integrated systems. DC drive technology has

proven to be extremely reliable and is ideally suited to web handling,

winders, slitters, extruders, wire drawing, converting lines, and plastics

production. The Quantum III meets the many requirements of these industries.

In addition to the features of the Mentor II, the Quantum III drive includes:

High speed

semiconductor fusing

115 VAC control interface

DC loop contactor (with DB pole up to 250 HP @ 480 VAC)

Accepts AC tachometer feedback DC output fuse on all models

-

Microprocessor Based Digital DC Drive

-

5 to 1000 HP, 3 phase,

208 / 230 / 380 / 480 VAC

-

Regenerative and non-regenerative models

-

RS485 serial communications

-

Extensive fieldbus communication

capabilities

-

Plug-in 32-bit application coprocessor

card (MD29)

-

MentorSoft, Windows

based drive configuration tool

-

Complete Motor Solutions

Applications

Many DC drive applications are for retrofit systems to improve the

performance and prolong the life of existing plants and machinery. New

applications for DC drives include:

- High Power applications

- Ski lifts

- Printing Presses

- Heavy Moveable Structures

- Lumber and Paper Milling

- Dual-turret winding

- Plastic and Rubber Extrusion

- Cranes, Hoists, and Cabling

- Iron, Steel and Glassworks

- Tilt Vessels, Coilers, Spoolers

- Metal Fabrication and Wire drawing

- Winding and unwinding

- Pulp and Paper processing

- Metal Rolling and processing

Benefits

- Powerful onboard intelligence allows the drives functionality to be

finely customized to the application and allows the removal of

troublesome analog control circuits

- Standard winder and flying shear software allow Mentor to be

integrated quickly and easily

- Modular approach to high power drives allows multiple Quantum III

drives to be connected in parallel or series to economically achieve the

required motor current and voltage rating

- MentorSoft, a windows based software, provides an intuitive

environment for configuring the drives functionality

- Our knowledge and experience in DC drive systems allows us to

recommend the best solution for your individual circumstances

- Quantum III integrates closely with the Control Techniques AC drives

using CTNet, drive-to-drive communications

- Regenerative and non-regenerative modules available to suit your

application

- Fieldbus options including Profibus and DeviceNet allow Mentor to be

integrated within an automation system

- Worldwide expertise and support

In addition to the features of the Mentor II, the Quantum III drive

includes:

- High speed semiconductor fusing

- 115 VAC control interface

- DC loop contactor (with DB pole up to 250 hp @ 480 VAC)

- Accepts AC or DC tachometer feedback, and encoder feedback

- DC output fuse on all Regen models

Internal field current output varies by frame size.

- Frame Size 1 to 8A, current controlled with field

weakening

- Frame Size 2A and 2B to 10A, fixed voltage use

FXM5 for field current control

- Frame Size 2C and 2D to 20A, fixed voltage

use FXM5 for field current control

Optional FXM5 external field controller for field currents up to 90A

- Digital link for field control from Mentor II or

Quantum III

- Standalone control mode

- Field weakening

- Field economy mode

FXM5 Field

Control 20, 50, 90A Models

Quantum III flexibility comes from the MD options interface; this allows

communications and programmable control to be added onboard the drive

itself. The following options are available:

Field Regulator

FXM5

Optional FXM5 external field controller

Communications

MD24 Profibus DP

Optional Profibus DP communications card

MD25 DeviceNet

Optional DeviceNet communications card

MD-IBS Interbus

Optional Interbus communications card

Programmable Control

MD29 Programmable Controller

Optional programmable controller (32-bit coprocessor)

MD29AN Programmable Controller with CTNet

Optional programmable controller (32-bit coprocessor) with CTNet

drive-to-drive communications

Remote I/O

CTNet I/O

Flexible I/O system for remote connectivity using Control Techniques

CTNet Drive-to-drive network

Control Techniques software suite makes it easy to access the complete

feature set of our drives. These tools provide quick setup of the

drive, optimize tuning, configuration back-up, programmable control and communications

link set up.

- MentorSoft - Drive configuration

- CTScope - Software oscilloscope

- SyPTPro - Ladder program editor

- CTOPCServer - OPC compliant server for interfacing with Control

Techniques drives

The Software tools communicate using CTNet, Serial or USB connections.

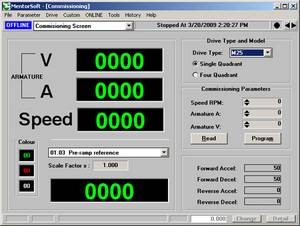

MentorSoft

MentorSoft is a complimentary Windows™-based drive configuration tool

designed to simplify the process of drive system design, set up, and

diagnostics. The software enables the complete control and display of all

parameters within a drive. The software also provides valuable drive data

storage, retrieval and programming functions. MentorSoft can be used

offline, in the office, or online on the plant floor.

Parameter programming and monitoring may be done using the parameter

tables or dynamic graphical flow diagrams. As on the drives parameters

are grouped into logical menus of related parameters. Help menus and

parameter descriptions are accessible by simply double clicking on the

parameter of interest. It allows you to:

- Easily configure the drive using wizards

- Read, save and load drive configuration settings

- Monitor drive parameters and status

- Visualize and modify the configuration with live animated diagrams

MentorSoft is free of charge and can be obtained by clicking the

download tab on this page.

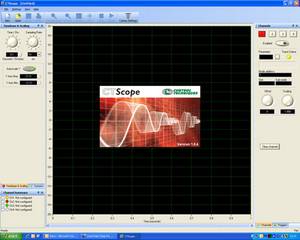

CTScope

CTScope is a full featured software oscilloscope for viewing and

analyzing changing values within the drive. The time base can be set

to give high speed capture for tuning or intermittent capture for longer

term trends. The interface is based on a traditional oscilloscope,

making it familiar to engineers across the globe.

CTScope is free of charge and can be obtained by clicking the download

tab on this page.

SyPTPro

SyPTPro is a full featured automation development environment that can

be used for creating solutions to single or multiple drive applications. The

programming environment fully supports three industry standard programming

languages: Function Block, Ladder and Structured Text. Motion is configured

using PLC open function blocks that support a master and slave axis

configuration.

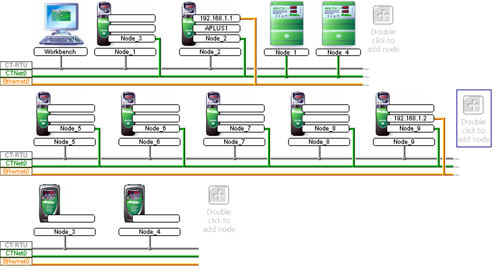

SyPTPro is also used to configure CTNet, a high speed drive-to-drive

network that links together multiple drives, SCADA, operator panels and

I/O to form an intelligent networked system.

Click here to download a demo version of SyPTPro, the full

version can be purchased through your local Drive Center.

CT OPC Sever

CTOPCServer is an OPC compliant server that allows PCs to communicate

with Control Techniques' drives. The server supports communication

using CTNet, Serial RS485 and USB. OPC is a standard interface on

SCADA packages and is widely supported within Microsoft products. The

server is supplied free of charge and can be obtained by clicking the

download tab on this page.

|

|

|

|

|

|

|

|

Motor

HP

|

Output

Current

|

Field

Output Current

|

Non-Regen

Catalog

Number (a)

|

Regen

Catalog

Number (a)

|

|

240V

|

380V

|

A

(c)

|

|

3 to 10

|

5 to 20

|

38

|

|

9500-8302

|

9500-8602

|

|

15

|

25 to 30

|

55

|

8A

Current

Regulated

|

9500-8303

|

9500-8603

|

|

20 to 30

|

40 to 60

|

106

|

9500-8305

|

9500-8605

|

|

40 to 50

|

75 to 100

|

172

|

9500-8306

|

9500-8606

|

|

75

|

150

|

255

|

9500-8307

|

9500-8607

|

|

100

|

200

|

338

|

20A

Fixed

Voltage

B

|

9500-8308

|

9500-8608

|

|

125

|

250

|

428

|

9500-8309

|

9500-8609

|

|

150

|

300

|

508

|

9500-8310

|

9500-8610

|

|

200

|

400

|

675

|

9500-8311

|

9500-8611

|

|

250

|

500

|

820

|

20A

Fixed

Voltage

B

|

9500-8315

|

9500-8615

|

|

300

|

600

|

985

|

9500-8316

|

9500-8616

|

|

-

|

700

|

1150

|

9500-8317

|

9500-8617

|

|

400

|

800

|

1250

|

9500-8318

|

9500-8618

|

|

-

|

900

|

1470

|

9500-8319

|

9500-8619

|

|

500

|

1000

|

1850

|

9500-8320

|

9500-8620

|

|

|

|

|

|

|

|

(A)

(B)

(C)

|

Drive includes DC loop contactor,

input fuses and 120VAC interface

For Filed control, add external field regulator P/N FXM20

Ambient temperature is 55 deg C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Catalogue Number

|

Size* (in)

H x W x D

|

Approx.

Weight (lbs)

|

|

9500-8302 thru 9500-8303

|

15 x 10 x10.5

|

44

|

|

9500-8602 thru 9500-8603

|

15 x 10 x10.5

|

44

|

|

9500-8305 thru 9500-8306

|

15 x 10 x 12.3

|

53

|

|

9500-8605 thru 9500-8606

|

15 x 10 x 12.3

|

53

|

|

9500-8307 thru 9500-8309

|

35 x 20.3 x 12

|

110

|

|

9500-8607 thru 9500-8609

|

35 x 20.3 x 12

|

110

|

|

9500-8310 thru 9500-8311

|

36 x 20.3 x 14

|

155

|

|

9500-8610 thru 9500-8611

|

36 x 20.3 x 14

|

155

|

|

9500-8315 thru 9500-8318

|

54 x 34 x 19

|

397

|

|

9500-8615 thru 9500-8618

|

72 x 34 x 19

|

475

|

|

9500-8319 thru 9500-8320

|

54 x 34 x 19

|

443

|

|

9500-8619 thru 9500-8620

|

72 x 34 x 19

|

525

|

|

* Approximate, not to be used for construction

purposes

|

|

|

|

|

|

Environment

|

|

Ambient Operating Temperature

|

0

- 55ºC (32-131ºF)

|

|

Cooling Method

|

Convection and forced convection. model dependant

|

|

Humidity

|

95% non-condensing at 55ºC (131ºF)

|

|

Storage Temperature

|

-40 to 55ºC (-40 to 131ºF)

|

|

Altitude

|

0 to 4000m (13,120 ft).

Derate 1% per 100m (328 ft)

between 1000m (3,280 ft) and 4000m (13,120 ft)

|

|

Enclosure

|

Chassis (IP00)

|

|

|

|

AC Supply requirements

|

|

Voltage

|

208 to 480 VAC -5%, +10%

|

|

Phase

|

3 Ø

|

|

Frequency

|

45 to 62 Hz

|

|

Efficiency

|

≥98%

|

|

|

|

Control

|

|

Feedback Methods

|

Armature Voltage (resolution 0.83volts)

DC Tachometer (resolution 0.1%)

Encoder (resolution 0.01%)

|

|

Field Control

|

Current regulated (9500-8306 / 8606 and smaller)

Voltage regulated (9500-8307 / 8607 and larger)

|

|

Analogue Input Resolution

|

12 bit (Qty 1), 10 bit (Qty 4)

|

|

Serial Communications

|

4-Wire RS422 or RS485, Optically-isolated

Protocol is ANSI x 3.28-2.5-A4

Baud rate is 4800 or 9600

|

|

|

|

Protection

|

|

AC Line Undervoltage Trip

|

180 VAC

|

|

MOV Voltage Transient Protection

|

Input transient suppression

|

|

Instantaneous Overcurrent Trip

|

300% armature current

|

|

Armature Open Circuit

|

Armature circuit is open

|

|

Drive Overload Trip

|

Inverse time, 150% for 30 seconds

|

|

Phase Loss Trip

|

Loss of input phase

|

|

Overtemperature Trip

|

Heatsink exceeds 100°C (212°F)

|

|

Motor Thermal Trip

|

Motor over-temp switch or Thermistor

|

|

Feedback Loss

|

Loss of motor feedback

|

|

Feedback Reversal

|

Tachometer or Encoder wired backwards

|

|

Field Loss

|

No field current

|

|

Field On

|

Field current during auto-tune

|

|

Field Overcurrent

|

Field current greater than field demand

|

|

Current Loop Loss

|

Loss of 4-20 mA reference

|

|

External Power Supply

|

Short circuit on + 24VDC user power supply

|

|

Power Supply

|

Internal power supply out of tolerance

|

|

Serial Communications Loss

|

Mode 3 serial comms data loss

|

|

Processor 1 Watchdog Trip

|

Main control processor fault

|

|

Processor 2 Watchdog Trip

|

Second control processor fault (MD29)

|

|

Hardware Fault

|

Hardware malfunction on control board

|

|

Memory Fault

|

Stored parameter checksum fault

|

|

External Trip

|

User interlock fault (programmed)

|

|

Software Fault (A29)

|

MD29 software fault

|

|

|

|

Approvals & Listings

|

|

Ul, cUL

|

File #E58592 Vol. 1 Section 19

|

|

CE

|

Designed for marking

|

|

ISO9002

|

Certified Manufacturing Facility

|

|

|